Chula Vista Portable Fire Extinguisher Six (6) Year Tests, Inspections and Maintenance

Every 6 years, stored pressure fire extinguishers that require a 12-year hydrostatic test (e.g. dry chemical extinguishers) must be emptied and proper maintenance procedures performed [see NFPA 10(98), Sec. 4-4.3]. The exception to this rule is non-rechargeable extinguishers, which are required to be removed from service 12 years from the date of manufacture. Again, this maintenance must be performed by an approved extinguisher servicing company.

Chula Vista Portable Fire Extinguisher Hydrostatic Tests, Inspections and Maintenance

At certain intervals, fire extinguishers are required to be pressure tested using water or some other non-compressible fluid to help prevent unwanted failure or rupture of the cylinder [see NFPA 10(98), Chapter 5]. This is called hydrostatic testing and includes both an internal and external examination of the cylinder. Because this testing requires special training and equipment, it needs to be performed by an approved extinguisher servicing company.

Hydrostatic testing intervals for fire extinguishers are outlined in NFPA 10(98), Sec. 5-2 and Table 5-2. Test intervals for some of the most commonly found extinguishers are as follows:

- Pressurized water, carbon dioxide and wet chemical extinguishers – every 5 years

- Dry chemical extinguishers – every 12 years

As mentioned earlier, the exception to the rule for hydrostatic testing is no rechargeable stored pressure extinguishers (e.g. dry chemical extinguishers), which are required to be removed from service 12 years from the date of manufacture.

Information only:

Some of you may have heard…

The 2007 edition of NFPA 10 contains a new requirement for the removal of dry chemical extinguishers manufactured prior to October, 1984 [see NFPA 10(07), Sec. 4.4.1]. Removal is to occur at the time of the next 6-year maintenance interval or next hydro test interval, whichever comes first. This requirement came about as the result of significant changes made to UL Standard 299, Dry Chemical Fire Extinguishers, based on fire testing conducted by UL, FEMA and NFPA.

Documentation Requirements

Almost as important as conducting required inspection, testing and maintenance is documenting the fact that it occurred. NFPA 10 requires that these services be properly recorded.

Chula Vista Hydrostatic Tests and Inspections

All commercial and industrial business owners shall assure that hydrostatic testing is performed by trained persons with suitable testing equipment and facilities. The commercial and industrial business owners shall assure that portable extinguishers are hydrostatically tested at the intervals listed in Table L-1 of this section, except under any of the following conditions:

- When the unit has been repaired by soldering, welding, brazing, or use of patching compounds

- When the cylinder or shell threads are damaged

- When there is corrosion that has caused pitting, including corrosion under removable name plate assemblies

- When the extinguisher has been burned in a fire

- When a calcium chloride extinguishing agent has been used in a stainless steel shell.

In addition to an external visual examination, the commercial and industrial business owners shall assure that an internal examination of cylinders and shells to be tested is made prior to the hydrostatic tests. In addition to an external visual examination, the commercial and industrial business owners shall assure that an internal examination of cylinders and shells to be tested is made prior to the hydrostatic tests. OSHA (Occupational Safety and Health Standards) Fire Protection: Portable fire extinguishers

TABLE L-1

Type of extinguishers |

Test interval (years) |

Soda acid (soldered brass shells) (until 1/1/82) |

(1) |

1Extinguishers having shells constructed of copper or brass joined by soft solder or rivets shall not be hydrostatically tested and shall be removed from service by January 1, 1982. (Not permitted)

Chula Vista Portable Fire Extinguisher Annual Tests, Inspections and Maintenance

“Maintenance” is a thorough examination and repair, as needed, of your facility’s portable fire extinguishers and is covered in NFPA 10(98), Sec. 4-4. Maintenance is required at least once a year – more frequently when indicated by a routine monthly inspection, as discussed earlier. Maintenance is also required whenever extinguishers undergo hydrostatic testing. Because maintenance is required to include a thorough examination of the mechanical parts, extinguishing agent and expelling means of each portable fire extinguisher, it must be performed by an approved extinguisher servicing company. A more detailed look at what annual maintenance entails can be found in NFPA 10(98), Tables A-4-4.4.2(a) and A-4-4.4.2(b). It should be noted that new tamper seals are required to be installed whenever maintenance is performed on rechargeable fire extinguishers [see NFPA 10(98), Sec. 4-4.2.1].

Chula Vista Monthly Tests and Inspections for Portable Fire Extinguishers

It's suggested by NFPA 10 standards and codes for portable fire extinguishers to perform monthly tests and inspections on your portable fire extinguishers which includes some of the following procedures:

- Location of where the fire extinguisher is installed

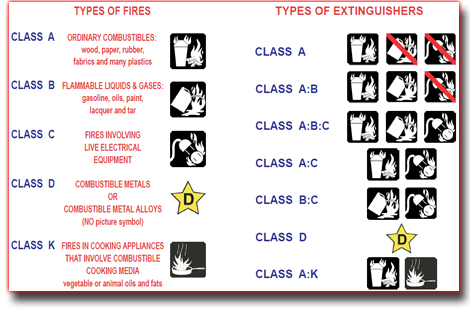

- Fire extinguisher placement (Class A Fire Hazards next to Class A Extinguishers)

- Make sure there are no obstructions for extinguisher access or visibility

- The fire extinguisher operating instructions shall remain legible and facing outward

- Ensure safety seals and tamper indicators are not broken or missing from fire extinguishers

- To accurately determine fire extinguisher contents the fullness will be weighed or “Hefting”

- Examine the fire extinguisher for obvious physical damage, corrosion, leakage or clogged nozzle

- Check fire extinguisher gauge or indicator to ensure located in operable position

- Wheeled units must also check condition of tires, wheels, carriage, hose, and nozzle

- All fire extinguishers must have HMIS in place on label

Monthly Fire Extinguisher Tests and Inspections Required by OSHA in Chula Vista

The following is an excerpt from OSHA regarding residential, commercial and industrial fire extinguisher tests, inspections, refills, recharges, hydrostatic testing, monthly inspections, annual inspections, and 6 & 12 year hydrostatic tests, inspections and required service maintenance.

1910.157(e)(2)

Portable extinguishers or hose used in lieu thereof under paragraph (d)(3) of this section shall be visually inspected monthly.

1910.157(e)(2)

Portable extinguishers or hose used in lieu thereof under paragraph (d)(3) of this section shall be visually inspected monthly.1910.157(e)(3)

The employer shall assure that portable fire extinguishers are subjected to an annual maintenance check. Stored pressure extinguishers do not require an internal examination. The employer shall record the annual maintenance date and retain this record for one year after the last entry or the life of the shell, whichever is less. The record shall be available to the Assistant Secretary upon request.1910.157(e)(4)

The employer shall assure that stored pressure dry chemical extinguishers that require a 12-year hydrostatic test are emptied and subjected to applicable maintenance procedures every 6 years. Dry chemical extinguishers having non-refillable disposable containers are exempt from this requirement. When recharging or hydrostatic testing is performed, the 6-year requirement begins from that date...1910.157(e)(5)

1910.157(e)(5)

The employer shall assure that alternate equivalent protection is provided when portable fire extinguishers are removed from service for maintenance and recharging.1910.157(f)

Hydrostatic testing.1910.157(f)(1)

The employer shall assure that hydrostatic testing is performed by trained persons with suitable testing equipment and facilities.1910.157(f)(2)

The employer shall assure that portable extinguishers are hydrostatically tested at the intervals listed in Table L-1 of this section, except under any of the following conditions:1910.157(f)(2)(i)

When the unit has been repaired by soldering, welding, brazing, or use of patching compounds;1910.157(f)(2)(ii)

When the cylinder or shell threads are damaged;1910.157(f)(2)(iii)

When there is corrosion that has caused pitting, including corrosion under removable name plate assemblies;1910.157(f)(2)(iv)

When the extinguisher has been burned in a fire; or1910.157(f)(2)(v)

When a calcium chloride extinguishing agent has been used in a stainless steel shell.1910.157(f)(3)

In addition to an external visual examination, the employer shall assure that an internal examination of cylinders and shells to be tested is made prior to the hydrostatic tests.

TABLE L-1

| Type of extinguishers | Test interval (years) |

| Soda acid (soldered brass shells) (until 1/1/82) Soda acid (stainless steel shell) Cartridge operated water and/or antifreeze Stored pressure water and/or antifreeze Wetting agent Foam (soldered brass shells) (until 1/1/82) Foam (stainless steel shell) Aqueous Film Forming foam (AFFF) Loaded stream Dry chemical with stainless steel Carbon Dioxide Dry chemical, stored pressure, with mild steel, brazed brass or aluminum shells Dry chemical, cartridge or cylinder operated, with mild steel shells Halon 1211 Halon 1301 Dry powder, cartridge or cylinder operated with mild steel shells |

(1) 5 5 5 5 (1) 5 5 5 5 5 12 12 12 12 12 |

1) Extinguishers having shells constructed of copper or brass joined by soft solder or rivets shall not be hydrostatically tested and shall be removed from service by January 1, 1982. (Not permitted)

..1910.157(f)(4)1910.157(f)(4)

The employer shall assure that portable fire extinguishers are hydrostatically tested whenever they show new evidence of corrosion or mechanical injury, except under the conditions listed in paragraphs (f)(2)(i)-(v) of this section.1910.157(f)(5)

The employer shall assure that hydrostatic tests are performed on extinguisher hose assemblies which are equipped with a shut-off nozzle at the discharge end of the hose. The test interval shall be the same as specified for the extinguisher on which the hose is installed.1910.157(f)(6)

The employer shall assure that carbon dioxide hose assemblies with a shut-off nozzle are hydrostatically tested at 1,250 psi (8,620 kPa).1910.157(f)(7)

The employer shall assure that dry chemical and dry powder hose assemblies with a shut-off nozzle are hydrostatically tested at 300 psi (2,070 kPa).1910.157(f)(8)

Hose assemblies passing a hydrostatic test do not require any type of recording or stamping.1910.157(f)(9)

The employer shall assure that hose assemblies for carbon dioxide extinguishers that require a hydrostatic test are tested within a protective cage device...1910.157(f)(10)

1910.157(f)(10)

The employer shall assure that carbon dioxide extinguishers and nitrogen or carbon dioxide cylinders used with wheeled extinguishers are tested every 5 years at 5/3 of the service pressure as stamped into the cylinder. Nitrogen cylinders which comply with 49 CFR 173.34(e)(15) may be hydrostatically tested every 10 years.1910.157(f)(11)

The employer shall assure that all stored pressure and Halon 1211 types of extinguishers are hydrostatically tested at the factory test pressure not to exceed two times the service pressure.1910.157(f)(12)

The employer shall assure that acceptable self-generating type soda acid and foam extinguishers are tested at 350 psi (2,410 kPa).1910.157(f)(13)

Air or gas pressure may not be used for hydrostatic testing.1910.157(f)(14)

Extinguisher shells, cylinders, or cartridges which fail a hydrostatic pressure test, or which are not fit for testing shall be removed from service and from the workplace.1910.157(f)(15)(i)

The equipment for testing compressed gas type cylinders shall be of the water jacket type. The equipment shall be provided with an expansion indicator which operates with an accuracy within one percent of the total expansion or .1cc (.1mL) of liquid.1910.157(f)(15)(ii)

The equipment for testing non-compressed gas type cylinders shall consist of the following:..1910.157(f)(15)(ii)(A)

1910.157(f)(15)(ii)(A)

A hydrostatic test pump, hand or power operated, capable of producing not less than 150 percent of the test pressure, which shall include appropriate check valves and fittings;1910.157(f)(15)(ii)(B)

A flexible connection for attachment to fittings to test through the extinguisher nozzle, test bonnet, or hose outlet, as is applicable; and1910.157(f)(15)(ii)(C)

A protective cage or barrier for personal protection of the tester, designed to provide visual observation of the extinguisher under test.1910.157(f)(16)

The employer shall maintain and provide upon request to the Assistant Secretary evidence that the required hydrostatic testing of fire extinguishers has been performed at the time intervals shown in Table L-1. Such evidence shall be in the form of a certification record which includes the date of the test, the signature of the person who performed the test and the serial number, or other identifier, of the fire extinguisher that was tested. Such records shall be kept until the extinguisher is hydrostatically retested at the time interval specified in Table L-1 or until the extinguisher is taken out of service, whichever comes first.1910.157(g)

Training and education.1910.157(g)(1)

Where the employer has provided portable fire extinguishers for employee use in the workplace, the employer shall also provide an educational program to familiarize employees with the general principles of fire extinguisher use and the hazards involved with incipient stage fire fighting.1910.157(g)(2)

The employer shall provide the education required in paragraph (g)(1) of this section upon initial employment and at least annually thereafter.1910.157(g)(3)

The employer shall provide employees who have been designated to use fire fighting equipment as part of an emergency action plan with training in the use of the appropriate equipment.1910.157(g)(4)

The employer shall provide the training required in paragraph (g)(3) of this section upon initial assignment to the designated group of employees and at least annually thereafter.