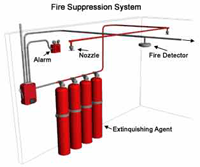

NFPA 12 + 17 Fire Suppression Inspections, Tests & Maintenance in San Diego

NFPA 101(00), Sec. 9.2.3 requires that commercial cooking equipment be in accordance with NFPA

96, Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations. NFPA

101(00), Sec. 2.1.1 references the 1998 edition of the standard. NFPA 96(98), in turn, references four

other NFPA standards applicable to automatic fire-extinguishing systems installed to protect kitchen

hood systems and cooking equipment [see NFPA 96(98), Sections 7-2.2.1 and 12-1]:

• NFPA 12(98), Standard on Carbon Dioxide Extinguishing Systems

• NFPA 13(96), Standard for the Installation of Sprinkler Systems

• NFPA 17(98), Standard for Dry Chemical Extinguishing Systems

• NFPA 17A(98), Standard for Wet Chemical Extinguishing Systems

Dry Chemical Fire Suppression Inspections, Tests and Maintenance in San Diego

Dry chemical fire suppression systems provide protection for many flammable and combustible liquid (Class B) fire hazards. They are particularly suited for outdoor environments where concerns about freezing prevent the installation of water-based systems.

The system owner is responsible for a monthly inspection to ensure the equipment remains in an operable condition. The inspection must be conducted in accordance with the manufacturer’s listed installation and maintenance manual or owner’s manual.

The inspection should include a check of the following components to verify that:

- Neither the protected equipment nor the hazard has been replaced, modified, or relocated. In this example, there should be no changes to the fuel dispensing equipment.

- The extinguishing system is in its proper location. The discharge pipe should not be bent or otherwise damaged.

- The manual release devices are unobstructed and accessible to motorists or the station operator.

- The tamper indicators and seals are intact.

- The maintenance tag or certificate is in place.

- The system shows no physical damage or condition that might prevent operation.

- The pressure gauge(s), if provided, are in the operable range.

- The nozzle blow off caps, where provided, are intact and undamaged. (There are no nozzle blow off caps on the pictured system.)

The inspection date and the initials of the person performing the inspection should be recorded, and the records maintained until the next semiannual service.

At least semiannually, maintenance shall be conducted in accordance with the manufacturer’s listed installation and maintenance manual. This maintenance should include

- A check to see that the hazard has not changed;

- An examination of all detectors, expellant gas container(s), agent container(s), releasing devices, piping, hose assemblies, nozzles, signals, and all auxiliary equipment;

- Verification that the agent distribution piping is not obstructed; and \

- Examination of the dry chemical.

If there is evidence of caking, the dry chemical must be discarded and the system recharged in accordance with the manufacturer’s instructions.

For additional information, refer to the National Fire Protection Association (NFPA) 17,Standard for Dry Chemical Extinguishing Systems.

San Diego Restaurant Kitchen Hood Fire Suppression Systems Inspections, Tests and Maintenance

The entire exhaust system (hood, grease removal devices, fans and ducts) for kitchen cooking equipment needs to be thoroughly inspected at least every 6 months to ensure that it’s free of grease accumulations [see NFPA 96(98), Sec. 8-3.1 and Table 8-3.1]. This inspection must be conducted by a company or person properly trained and qualified to perform such a service. The authority having jurisdiction (AHJ) may require a certificate or other proof of such training.

If this inspection reveals deposits from grease-laden vapors, the entire exhaust system must be cleaned to bare metal by a properly trained, qualified and certified company or person(s) acceptable to the AHJ [see NFPA 96(98), Sec. 8-3.1.1]. It should be noted that:

- Cleaning to bare metal does not mean removing the paint from painted surfaces.

- After the exhaust system is cleaned to bare metal, it cannot be coated with powder or other substances.

- Flammable solvents or other flammable cleaning aids are not allowed to be used for cleaning.

- At the start of the cleaning process, electrical switches that could be activated accidentally must be locked out (remember your lock out-tag out procedures).

- Components of the automatic fire-extinguishing system protecting the kitchen cooking equipment cannot be rendered inoperable during the cleaning process unless they are being serviced by a properly trained and qualified person.

- Special care needs to be taken to ensure that cleaning chemicals are not applied on fusible links or other detection devices of the automatic fire-extinguishing system.

When the cleaning process is completed:

- All electrical switches and system components must be returned to an operable state,

- All access panels and cover plates must be replaced, and

- Dampers and diffusers must be positioned for proper airflow.

San Diego Kitchen hood fire-extinguishing system

The standards applicable to automatic dry- or wet-chemical fire-extinguishing systems protecting kitchen cooking equipment [see NFPA 17(98), Sec. 9-2.1/NFPA 17A(98), Sec. 5-2.1] require that such systems be inspected monthly to ensure that:

- The extinguishing system is in proper operation

- Manual actuators are unobstructed

- Tamper indicators and seals are intact

- The maintenance tag or certificate is in place

- There is no obvious physical damage

- Pressure gauges, if provided, are in operable range

In addition, an inspection and servicing of the kitchen hood fire-extinguishing system by properly trained and qualified persons is required at least every 6 months [see NFPA 96(98), Sec. 8-2].

- This service must include a check of all actuation components, including remote manual pull stations, mechanical or electrical devices, detectors, actuators and fire-actuated dampers to ensure that they are in operable condition [see NFPA 96(98), Sec. 8-2.1].

- A visual inspection of fire alarm interconnect switches is also required [see NFPA 72(99), Table 7-3.1]. Fusible links and automatic sprinkler heads are required to be replaced at least annually, but may have to be replaced more frequently if a visual inspection shows that to be necessary [see NFPA 96(98), Sec. 8-2.2].

- By exception, bulb-type sprinklers or spray nozzles do not need to be replaced if an annual examination shows no buildup of grease or other material on the sprinkler or spray nozzles.

Fire alarm interconnect switches are required to be tested annually by mechanically or electrically operating the switch to verify receipt of a signal at the fire alarm control panel [see NFPA 72(99), Tables 7-3.2 and 7-2.2]. This testing should be performed as part of the annual test conducted of the building fire alarm system. The equipment manufacturer may have additional maintenance requirements that should be followed in order to ensure proper operation of the system and maintain applicable warranties. The standards applicable to automatic dry- or wet-chemical fire-extinguishing systems also contain inspection requirements that must be followed, including:

San Diego Fire Suppression Hydrostatic Tests, Inspections and Maintenance

- In accordance with NFPA 17(98), Sections 9-3.1 and 9-5, cylinders for dry chemical kitchen hood extinguishing systems must be:

- Examined every 6 years to check for caking

- Hydrostatically tested every 12 years

- In accordance with NFPA 17A(98), Sec. 5-5, cylinders for wet chemical kitchen hood extinguishing systems must be hydrostatically tested every 12 years

DOCUMENT Your Tests, Inspections and Service

Exhaust system:

Both NFPA 96 many state fire codes require that exhaust system cleanings be recorded [see NFPA 96(98]. These records must include the extent, time and date of cleaning. When a vent cleaning contractor is used, the contractor must be able to provide you with a certificate showing the date of any inspections or cleanings performed. In addition, the contractor is required to display a tag within the kitchen indicating the date of the cleaning and the name of the servicing company and identifying any areas that were not cleaned on the date of the service.

Fire Protection Systems that Require Scheduled Tests, Inspections and Maintenance in San Diego

Types of Fire Prevention Systems Requiring Tests and Inspections |

| Sprinkler and Standpipe Systems. |

| Engineered CO2 fire suppression systems. |

| Engineered clean agent fire suppression systems. |

| Engineered foam fire suppression systems. |

| Engineered dry chemical fire suppression systems. |

| Engineered water mist fire suppression systems. |

| Residential fire suppression systems (NFPA 13D systems) |

| Pre-engineered CO2 fire suppression systems only. |

| Pre-engineered clean agent fire suppression systems only. |

| Pre-engineered foam fire suppression systems only. |

| Pre-engineered dry chemical fire suppression systems only. |

| Pre-engineered wet chemical fire suppression systems only. |

| Pre-engineered water mist suppression systems. |

San Diego Special Agent Extinguishing Systems Test and Inspection Checklist

When your fire Special Agent Extinguishing Systems is tested, inspected or serviced by local fire departments, state licensed fire protection companies, certified fire protection technicians and/or fire safety engineers. They may use a form from NFPA similar to the one below when a test, inspection or service is completed for your Special Agent Extinguishing System.

For a new versions visit NFPA Tests and Inspections Forms

Inspection Checklist

Special Agent Extinguishing Systems

Building: ______________________________________________________________________

Address: ______________________________________________________________________

Inspector: ___________________________________ Date: ___________________________

Date of Last Inspection: _____________________ Outstanding Violations: ❑ Yes ❑ No

General

Type of special agent extinguishing system:

❑ Wet chemical

❑ Dry chemical

❑ Halon

❑ Carbon dioxide

❑ Other: ________________________________________

What does the system protect? _____________________________________________________

Date system installed: ______________________________

Were building alterations/renovations made since

last inspection? ❑ Yes ❑ No

Was a new special agent extinguishing system added

since last inspection? ❑ Yes ❑ No

Was any system alteration made since last inspection? ❑ Yes ❑ No

Is system connected to building fire alarm? ❑ Yes ❑ No ❑ N/A*

Automatic Shutdown

What is fuel source?

❑ Electricity

❑ Gas

❑ Other: _______________________________________

Nozzles

Are caps in place? ❑ Yes ❑ No ❑ N/A

Are nozzles properly oriented to protect hazard? ❑ Yes ❑ No ❑ N/A

Are there signs of damage? ❑ Yes ❑ No ❑ N/A

Manual Releases

Are manual releases clear and unobstructed? ❑ Yes ❑ No ❑ N/A

Are they properly identified? ❑ Yes ❑ No ❑ N/A

System Pressure Gauges

Are system pressure gauges in proper operating range? ❑ Yes ❑ No ❑ N/A

Are they readily visible? ❑ Yes ❑ No ❑ N/A

*N/A (not applicable) means there’s no such feature in the building.

Form A-12 Inspection Checklist to Accompany Chapter 17

Copyright © 2002 National Fire Protection Association (Page 1 of 2)

611

Gaseous Agent Systems (Halon or CA2)

Are room doors self-closing or automatic closing? ❑ Yes ❑ No ❑ N/A

Quarterly Inspections and Tests

Are quarterly inspections and tests recorded? ❑ Yes ❑ No

Semiannual Inspections and Tests

Are semiannual inspections and tests recorded? ❑ Yes ❑ No

Annual Inspections and Tests

Are annual inspections and tests recorded? ❑ Yes ❑ No

5-Year Tests

Are 5-year tests recorded? ❑ Yes ❑ No ❑ N/A

• Were CO2 system hoses tested? ❑ Yes ❑ No ❑ N/A

12-Year Tests

Are 12-year tests recorded? ❑ Yes ❑ No ❑ N/A

• Were CO2 system cylinders tested? ❑ Yes ❑ No ❑ N/A

• Were CO2 systems discharge tested? ❑ Yes ❑ No ❑ N/A

Notes: ________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Form A-12 Continued

Copyright © 2002 National Fire Protection Association (Page 2 of 2)

San Diego Clean Agent Extinguishing Systems Test and Inspection Checklist

For a new versions visit NFPA Tests and Inspections Forms

Inspection Checklist

Clean Agent Extinguishing Systems

Building: ______________________________________________________________________

Address: ______________________________________________________________________

Inspector: __________________________ Date: _____________________________________

Date of Last Inspection: _____________________ Outstanding Violations: ❑ Yes ❑ No

General

Agent type: ____________________________________________________________________

Clean agent extinguishing system protects:____________________________________________

Date system installed: ____________________________________________________________

Were building alterations/renovations made since

last inspection? ❑ Yes ❑ No

Was new clean agent extinguishing system added since

last inspection? ❑ Yes ❑ No

Was any system alteration made since last inspection? ❑ Yes ❑ No

Is system connected to building fire alarm? ❑ Yes ❑ No ❑ N/A*

Automatic Shutdown

What is fuel source?

❑ Electricity

❑ Gas

❑ Other: __________________________________________

Nozzles

Are caps in place? ❑ Yes ❑ No ❑ N/A

Are nozzles properly oriented to protect hazard? ❑ Yes ❑ No ❑ N/A

Are there signs of damage? ❑ Yes ❑ No ❑ N/A

Manual Releases

Are manual releases clear and unobstructed? ❑ Yes ❑ No ❑ N/A

Are they properly identified? ❑ Yes ❑ No ❑ N/A

System Pressure Gauges

Are system pressure gauges in proper operating range? ❑ Yes ❑ No ❑ N/A

Are they readily visible? ❑ Yes ❑ No ❑ N/A

Room Doors

Are room doors self-closing or automatic closing? ❑ Yes ❑ No ❑ N/A

Quarterly Inspections and Tests Recorded

Are quarterly inspections and tests recorded? ❑ Yes ❑ No

*N/A (not applicable) means there’s no such feature in the building.

Form A-13 Inspection Checklist to Accompany Chapter 18

Copyright © 2002 National Fire Protection Association (Page 1 of 2)

613

Semiannual Inspections and Tests Recorded

Are semiannual inspections and tests recorded? ❑ Yes ❑ No

Annual Inspections and Tests Recorded

Are annual inspections and tests recorded? ❑ Yes ❑ No

5-Year Tests

Are 5-year tests recorded? ❑ Yes ❑ No ❑ N/A

• Were system hoses tested? ❑ Yes ❑ No ❑ N/A

Notes: _______________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

Form A-13 Continued

Copyright © 2002 National Fire Protection Association (Page 2 of 2)

San Diego Portable Fire Extinguishers Test and Inspection Checklist

For a new versions visit NFPA Tests and Inspections Forms

Inspection Checklist

Portable Fire Extinguishers

Building: _____________________________________________________________________

Address: _____________________________________________________________________

Inspector: _________________________ Date: _____________________________________

Date of Last Inspection: ________________________ Outstanding Violations: ❑ Yes ❑ No

General

Are fire extinguishers provided? ❑ Yes ❑ No

Mounting

Are extinguishers properly mounted? ❑ Yes ❑ No

Are any extinguishers blocked? ❑ Yes ❑ No

Does distribution appear adequate? ❑ Yes ❑ No

Monthly Inspections

Are monthly inspections recorded? ❑ Yes ❑ No ❑ N/A*

• On tag on extinguisher? ❑ Yes ❑ No ❑ N/A

• On form? ❑ Yes ❑ No ❑ N/A

Annual Maintenance

Are records provided of annual maintenance? ❑ Yes ❑ No

*N/A (not applicable) means there’s no such feature in the building.

Notes: _______________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

Form A-14 Inspection Checklist to Accompany Chapter 19